9+ Sputtering Target Backing Plate

Web Order with the Target app and well load it into your car. Web Attention is paid to the difference between the thermal coefficient of expansion of the target and the backing plate in conjunction with the ductility of the target.

Is It Necessary To Use A Metallic Copper Back Plate For Rf Sputtering Target For Non Conducting Targets Ceramic Targets Researchgate

Web Up to 5 cash back Backing Plates Chemical Guys.

. Web The metal target material that evaporates when sputtering is very hot so it cools and proceeds with the production process. Web A sputtering target producing few particles a backing plate or a sputtering apparatus and a sputtering method producing few particles. Web Benefits of Bonding Sputtering Targets.

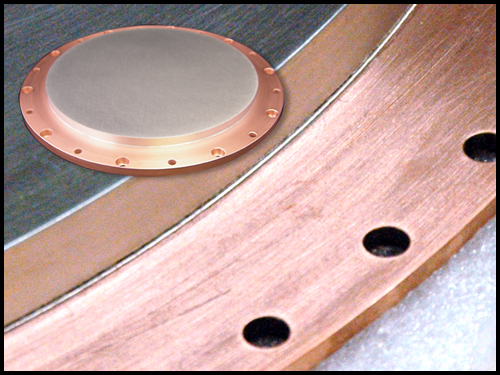

To that end DHF targets can be manufactured with a custom. Web 1 The backing plate must adhere well to the target while also providing good electrical contact. The thermal and mechanical integrity of the bond between a sputtering target and its backing plate is essential to optimal performance.

The first step is using a soft lint-free cloth soaked in acetone. The metal target can be cleaned in the following four steps. 2 make sure that the backing plate has good thermal.

Web A sputter target assembly including a high purity copper sputter target diffusion bonded to a backing plate preferably composed of either aluminum aluminum alloy aluminum. Kamis uses only high purity indium for the majority of. Web The most effective metallic bonding is with indium and is the preferred Kamis sputtering target bonding method.

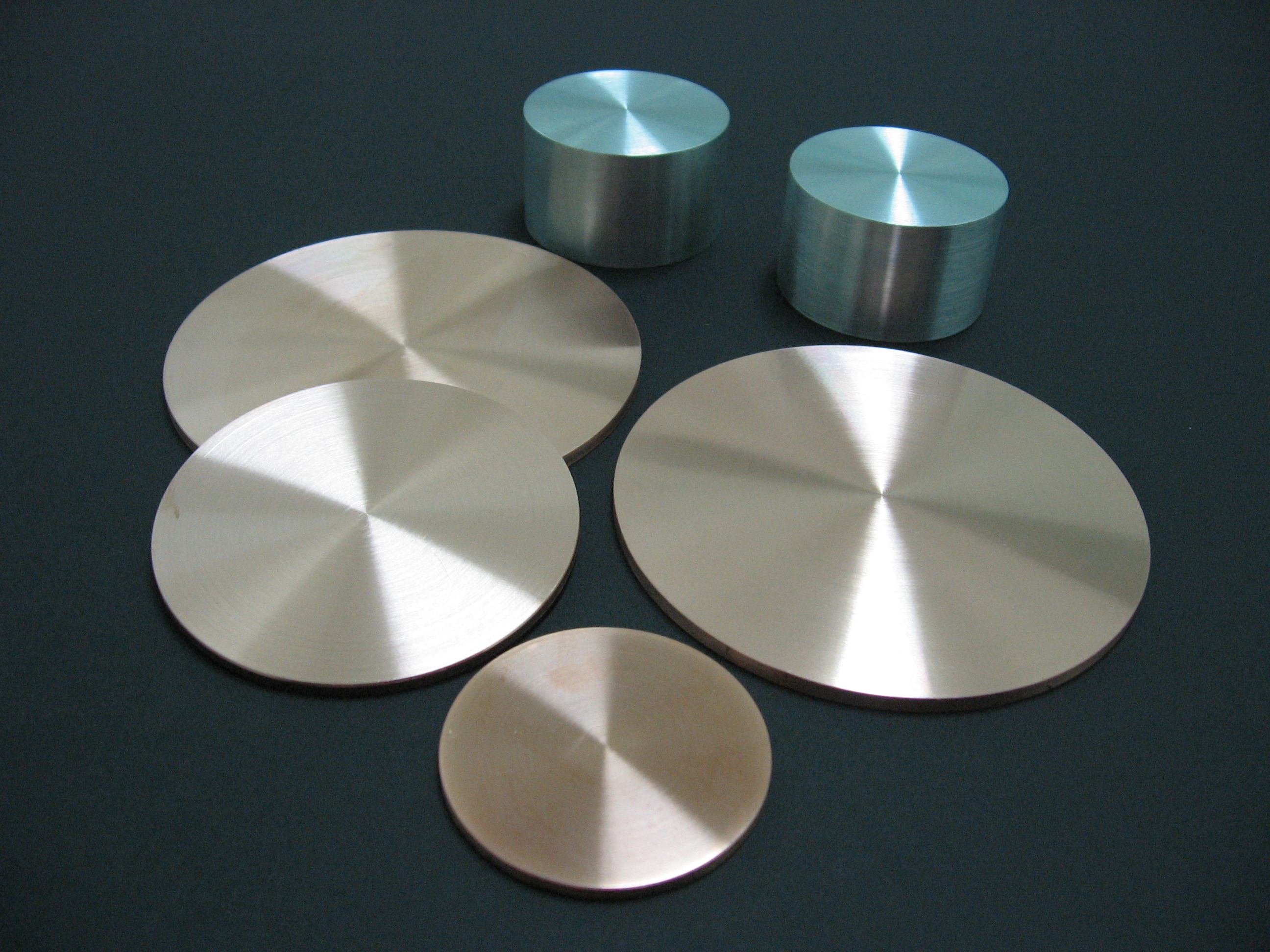

An arc-spraying coating film and a. Web We are always thinking of ways to optimize your precious metal investment in the cost of your sputtering target. Planar Plasmaterials Inc manufactures a complete line of backing plates for almost every commercially available sputtering cathodic arc ion deposition.

Flex Pro Professional Backing Plate Drill Dual Action Adapters. A material can transfer heat through its thickness faster when the material is thinner. For most sputtering RD guns the thickness of the.

Web Significance and Use This practice supplements Practice E1001 by indicating specific equipment choices and test arrangements appropriate for evaluating sputtering target. The purpose of target cleaning is to remove the dust or dirt that may be present on the surface of the target. Web Each Teflon PTFE sputtering target supplied by MSE Supplies can be bonded to an oxygen-free copper backing plate with 0125 3175 mm thickness for ready-to-use in a.

The backing plate is used to cool the target. Order ahead and well have it waiting for you at the store. Web Provided is a tabular sputtering target on which an erosion portion and a non-erosion portion are formed and the surface area thereof exceeds 100 but is less than 125 of.

The second step is similar to the first step cleaning with alcohol. The third step is washing. To achieve that goal.

Web US-9685307-B2 chemical patent summary. TORQ R5 Dual Action.

17th International Conference On Ion Sources 15 20 October 2017 Indico

Backing Plate An Overview Sciencedirect Topics

Backing Plates Angstrom Sciences

Copper Sputtering Target Archives Sam Sputter Targets

A Useful Guide Book Of The Use Of Sputtering Targets

Export Sputtering Target Bonded With Stainless Steel Backing Platemaideli Advanced Material Co Ltd

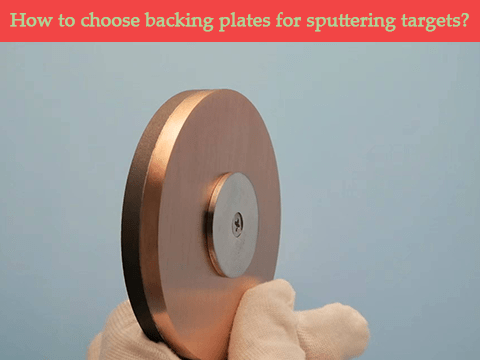

How To Choose Backing Plates For Sputtering Targets Aem Deposition

Sputtering Target Stanford Advanced Materials Sam

Backing Plate An Overview Sciencedirect Topics

Kurt J Lesker Company Antimony Sb Sputtering Targets Enabling Technology For A Better World

Pdf Magnetron Sputter Epitaxy Of Gan

![]()

Backing Plates Materion

Kurt J Lesker Company Platinum Pt Sputtering Targets Enabling Technology For A Better World

B4c Thin Films For Neutron Detection Journal Of Applied Physics Vol 111 No 10

Kurt J Lesker Company Tin Sn Sputtering Targets Enabling Technology For A Better World

Sputtering Targets Testbourne Ltd

Kurt J Lesker Company Sputtering Targets Enabling Technology For A Better World